The Complete Tarpaulin Material Guide: Choosing the Perfect Material for Your Needs

When selecting a tarpaulin for your specific application, the material choice can make all the difference between a successful project and costly disappointment. At Dunlop Tarpaulins, we’ve manufactured custom tarpaulins for over three decades, and we’re sharing our expert insights to help you make the optimal choice.

Understanding Tarpaulin Materials: The Core Options

A tarpaulin, or tarp, is a large, durable sheet made from materials like polyethylene, polyvinyl chloride (PVC), canvas, or mesh. These materials are typically waterproof or water-resistant, designed to provide protection against elements such as moisture, dust, and UV rays.

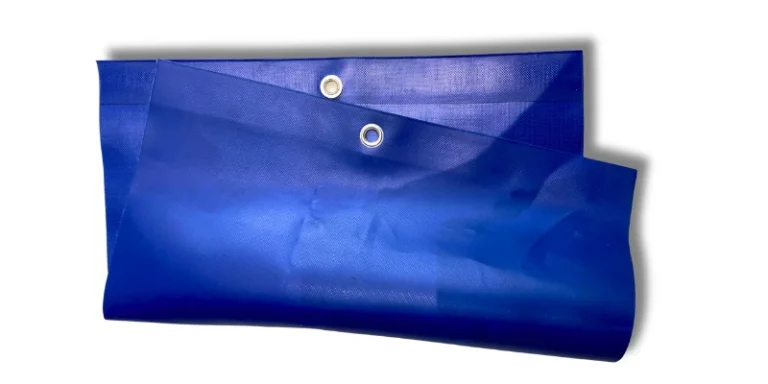

PVC-Coated Polyester Fabric

Best for: Heavy-duty industrial applications, long-term outdoor installations, and environments with chemical exposure.

PVC (polyvinyl chloride) coated tarpaulins represent the gold standard for professional applications where durability cannot be compromised.

Key advantages:

- Exceptional waterproofing capabilities (100% waterproof when properly sealed)

- Superior UV resistance with minimal degradation over time

- High tensile strength (typically 2000-3000N/5cm)

- Excellent resistance to chemicals, oils, and acids

- Fire-retardant options available (BS 7837 certified)

- Temperature stable from -30°C to +70°C

Real-world application: One of our clients in the construction industry used our heavy-duty 650gsm PVC tarpaulins on a 14-month building project through two British winters. The tarpaulins maintained structural integrity throughout, protecting millions in equipment and materials.

Polyethylene (PE) Tarpaulins

Best for: Temporary coverage, budget-conscious projects, and medium-duty applications.

PE tarpaulins offer an excellent balance between cost and performance, making them the most commonly used tarpaulin material worldwide.

Key advantages:

- Highly cost-effective (typically 50-60% cheaper than PVC)

- Lightweight and easy to handle

- Available in various densities (from 80gsm to 260gsm)

- Good water resistance with laminated options

- UV-stabilized versions available for better outdoor performance

Real-world application: Our agricultural clients regularly use 180gsm PE tarpaulins for seasonal hay storage, typically replacing them every 2-3 seasons – a cost-effective approach for temporary but essential protection.

Canvas Tarpaulins

Best for: Traditional applications, breathable coverage, and aesthetic requirements.

Traditional canvas remains popular for specific applications where breathability and natural aesthetics matter.

Key advantages:

- Natural breathability prevents condensation buildup

- Aesthetically pleasing for visible applications

- Water-resistant when properly treated (not fully waterproof)

- Environmentally friendly option

- Develops character with age

Real-world application: Heritage restoration projects frequently use our treated canvas tarpaulins, as they provide the necessary protection while maintaining the traditional appearance needed for historical structures.

Mesh Tarpaulins

Best for: Wind-exposed areas, shade requirements, and applications needing airflow.

Mesh tarpaulins offer a specialized solution when air circulation is as important as protection.

Key advantages:

- Reduces wind load by 60-90% depending on mesh density

- Provides UV protection while allowing air passage

- Prevents heat buildup under covered areas

- Available in various shade percentages (30-95% shade)

- Highly tear-resistant due to mesh structure

Real-world application: Our scaffolding clients consistently choose 220gsm mesh tarpaulins for high-rise projects, as they substantially reduce wind pressure while containing dust and debris.

Making Your Selection: Critical Factors to Consider

1.Project Duration

For projects under 6 months, standard PE tarpaulins often provide sufficient protection at optimal cost. For 1-3 years, consider reinforced PE or light PVC options. For 3+ years of continuous use, premium PVC represents the only truly economical choice when factoring replacement costs.

2.Environmental Conditions

Different materials handle environmental challenges differently:

| Condition | Recommended Material | Minimum Specification |

|---|---|---|

| High UV Exposure | UV-treated PVC | 450gsm with UV inhibitors |

| Chemical Exposure | Chemical-resistant PVC | 650gsm with specific chemical resistance |

| Extreme Cold | Arctic-grade PE or PVC | Cold-crack tested to -40°C |

| High Wind Areas | Mesh or reinforced PVC | Wind-tested to 100km/h |

| Fire Risk Areas | FR-rated PVC | Certified to BS 7837 |

3.Weight and Handling Requirements

Consider who will be handling the tarpaulin and how frequently it needs to be moved:

- Frequently moved by hand: Lightweight PE (80-120gsm)

- Occasionally repositioned: Medium PE or light PVC (180-450gsm)

- Permanently installed: Heavy-duty PVC (550gsm+)

4.Budget Considerations

While initial cost is important, calculate the true cost-per-month of protection:

- PVC tarpaulins initially cost more but typically last 3-5 times longer than PE

- Canvas requires regular retreatment costs

- Replacement labor costs often exceed material differences

Specialized Industry Applications

Construction Industry

Construction sites require different tarpaulin materials depending on the phase:

- Groundwork phase: Reinforced PE (180gsm+) for temporary coverage

- Structural phase: Mesh tarpaulins for scaffolding to reduce wind load

- Interior work phase: Heavy-duty PVC (650gsm+) for total moisture protection

Agricultural Applications

Agricultural tarpaulins face unique challenges:

- Hay and straw storage: Breathable treated canvas or UV-stabilized PE

- Machinery protection: PVC with UV inhibitors (550gsm+)

- Livestock area coverage: Reinforced PE with anti-condensation treatment

Transport and Logistics

For goods in transit:

- Regular deliveries: Lightweight PVC (450gsm) for ease of handling

- Container coverage: Heavy-duty PE with reinforced edges

- Long-term shipping: Marine-grade PVC with salt-water resistance

Caring for Your Tarpaulin: Material-Specific Maintenance

Proper care significantly extends the life of any tarpaulin:

- PVC tarpaulins: Clean quarterly with mild soap, avoid folding on crease lines when storing

- PE tarpaulins: Keep away from sharp edges, store completely dry

- Canvas: Retreat water-resistant coating annually, store in dry conditions

- Mesh: Remove accumulated debris regularly to prevent stretching

Custom Solutions: When Standard Materials Don’t Fit

Sometimes standard materials don’t address specific requirements. Our custom fabrication service can develop specialized solutions including:

- Composite materials combining PVC strength with PE lightness

- Multi-layer constructions for extreme environments

- Specialized coatings for unique chemical or temperature resistance

Conclusion: Making the Right Investment

Selecting the optimal tarpaulin material is ultimately about balancing immediate cost against longevity and performance requirements. The cheapest option rarely provides the best value when calculated over the full project duration.

For personalized advice on selecting the perfect tarpaulin material for your specific application, contact our technical team. With over 30 years of manufacturing experience, we can help you make a selection that provides reliable protection while maximizing your investment.

This guide was last updated: April 2025

FAQ

Find quick answers to common questions.

What is the most durable tarpaulin material?

PVC tarpaulin is widely regarded as the most durable due to its resistance to harsh weather conditions and long-term wear.

Can tarpaulins be used for long-term outdoor applications?

Yes, PVC and canvas tarps are ideal for long-term outdoor use, thanks to their durability and weather-resistant properties.

How do I clean and maintain my tarp?

Use mild soap and water to clean your tarp. Ensure it is thoroughly dried before storage, and repair any tears promptly to prolong its lifespan.

Are there eco-friendly tarpaulin options available?

Yes, canvas tarps and those made from recycled materials are eco-friendly alternatives to traditional plastic tarps.