Common Mistakes to Avoid When Installing HDPE Pond Liners

When it comes to creating a durable and beautiful pond, HDPE (High-Density Polyethylene) pond liners are a top choice. Known for their strength, flexibility, and eco-friendly properties, HDPE liners offer a long-lasting solution for pond construction. However, improper installation or handling can lead to issues that compromise their performance. This guide will help you avoid common mistakes when installing HDPE pond liners, ensuring your pond remains in excellent condition for years to come.

1. Choosing a Low-Quality HDPE Liner

Not all HDPE liners are the same. Opting for a low-quality liner might save money initially but can lead to cracks, leaks, and frequent repairs.

Mistake: Purchasing a thin or poorly manufactured HDPE liner.

Solution: Always invest in a high-grade HDPE liner with adequate thickness (at least 40 mil) and UV resistance. Reputable brands offer warranties and proven durability.

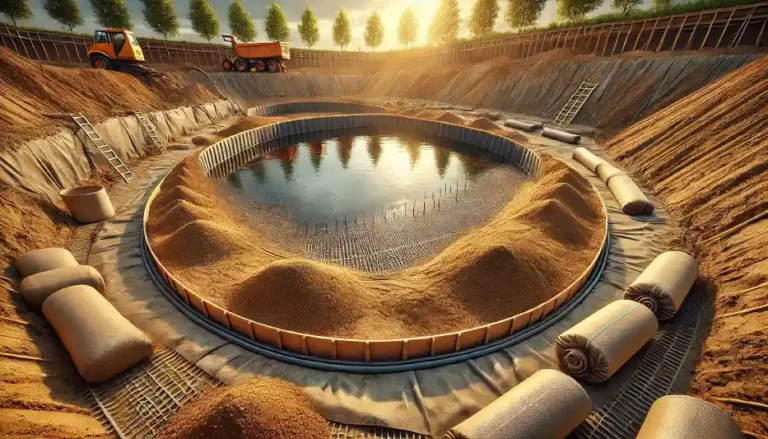

2. Skipping Proper Ground Preparation

Ground preparation is critical for protecting your HDPE liner from punctures and ensuring it lies flat.

Mistake: Installing the liner on rough, uneven terrain or rocky surfaces.

Solution: Clear the area of debris, sharp objects, and roots. Add a layer of sand or geotextile underlayment to provide a smooth and cushioned base for the HDPE liner.

3. Improper Measuring and Cutting

HDPE liners must be correctly sized to avoid stretching, overlaps, or exposed areas that can lead to leaks.

Mistake: Miscalculating the dimensions of the pond and cutting the liner incorrectly.

Solution: Use the formula:

Liner Width = Pond Width + (2 x Maximum Depth) + 2 feet (overlap allowance)

Liner Length = Pond Length + (2 x Maximum Depth) + 2 feet (overlap allowance)

Always measure twice and cut once. Leave extra material for anchoring and adjustments.

4. Neglecting to Use an Underlayment

Even though HDPE liners are puncture-resistant, they still need protection from sharp objects and pressure points.

Mistake: Placing the HDPE liner directly on the ground without a buffer layer.

Solution: Use a high-quality underlayment like geotextile fabric or sand to prevent punctures and extend the liner’s lifespan.

5. Failing to Remove Wrinkles and Air Pockets

Wrinkles and air pockets can create stress points in the HDPE liner, potentially leading to damage over time.

Mistake: Allowing the liner to wrinkle or trap air during installation.

Solution: Lay the liner carefully and smooth it out as you gradually fill the pond with water. Adjust the liner as needed to ensure a snug fit.

6. Overstretching the HDPE Liner

HDPE liners are flexible but should not be overstretched as this can reduce their durability and create weak points.

Mistake: Pulling the liner too tight to eliminate slack.

Solution: Allow the liner to settle naturally into the contours of the pond. Leave some slack to accommodate soil movement and temperature changes.

7. Using Improper Seaming Techniques

For larger ponds, you may need to join multiple sheets of HDPE liner. Improper seaming can result in leaks and structural issues.

Mistake: Using non-specialized adhesives or tapes for seaming.

Solution: Use heat welding or HDPE-specific seaming tape to create watertight seams. Ensure the surface is clean and dry before joining.

8. Exposing the Liner to Direct Sunlight

Although HDPE liners are UV-resistant, prolonged exposure to direct sunlight can still degrade them over time.

Mistake: Leaving the liner exposed around the edges.

Solution: Cover the edges of the liner with rocks, soil, or vegetation to protect it from UV rays. This also enhances the pond’s aesthetic appeal.

9. Ignoring Drainage and Overflow Design

A pond without proper drainage or overflow mechanisms can lead to waterlogging and stress on the liner.

Mistake: Neglecting to plan for overflow or drainage.

Solution: Incorporate a drainage system or overflow outlet into your pond design to manage excess water effectively.

10. Overlooking Regular Maintenance

Even the best HDPE liner requires routine maintenance to ensure its longevity and functionality.

Mistake: Failing to inspect and clean the pond periodically.

Solution: Remove debris, monitor water levels, and inspect the liner for signs of wear or damage. Early intervention can prevent minor issues from becoming major problems.

Conclusion

HDPE pond liners are an excellent choice for anyone looking to build a durable, eco-friendly, and cost-effective pond. By avoiding these common mistakes and following the proper installation techniques, you can ensure your pond liner lasts for decades. From site preparation to regular maintenance, each step is essential in creating a stunning water feature that stands the test of time. Choose HDPE for a reliable, high-performance pond liner that delivers lasting results.

FAQ

Find quick answers to common questions.