Custom Tarps: Durable Solutions for Superior Protection

When standard sizes and specifications fall short of your requirements, custom tarpaulin solutions provide the exact protection you need. At Dunlop Tarpaulins, we’ve spent decades perfecting the art of bespoke tarpaulin manufacturing to deliver tailored solutions for the most demanding applications across multiple industries.

Why Choose Custom Tarpaulins?

Standard tarpaulins often represent compromises—either too large (wasting material and creating handling difficulties) or too small (failing to provide adequate coverage). Custom tarpaulins eliminate these compromises by delivering precisely what your application demands.

Key Benefits of Custom-Made Tarpaulins

Perfect Fit Protection

Our custom tarpaulins are manufactured to your exact measurements, eliminating excess material and ensuring complete coverage of your assets. This precise fit minimizes movement in windy conditions and prevents water ingress at vulnerable points.

Material Optimized for Your Environment

Different environments place unique demands on protective coverings. Our custom solutions allow you to select the ideal material properties for your specific conditions:

- High UV exposure environments benefit from advanced UV stabilization

- Chemical exposure areas require specific resistant formulations

- High-wind zones need reinforced construction techniques

- Temperature extremes demand specialized material grades

Specialized Features When Needed

Custom manufacturing enables the integration of specialized features impossible with off-the-shelf products:

- Access points and hatches positioned exactly where required

- Ventilation panels to manage condensation

- Transparent sections for monitoring without exposure

- Reinforced mounting points aligned with your equipment

- Integration with existing structures and equipment

Branding and Identification Options

Custom tarpaulins create opportunities for powerful brand visibility:

- Company colors and logos clearly displayed

- Required safety information and warnings integrated into the design

- Site or equipment identification permanently applied

- High-visibility elements for improved safety

Our Custom Tarpaulin Manufacturing Process

Creating the perfect custom tarpaulin involves a methodical approach refined through years of manufacturing experience.

1. Detailed Consultation and Specification

Our process begins with understanding your exact requirements:

- Precise measurements of the coverage area

- Environmental conditions the tarpaulin will face

- Expected lifespan and usage patterns

- Any specialized features or access requirements

- Installation and securing considerations

Industry Insight: During consultation, our experts often identify potential issues clients haven’t considered. For example, a construction client initially requested a standard shape until our site assessment revealed that a custom cutout would allow for critical equipment access without removing the entire cover.

2. Material Selection and Engineering

Based on your requirements, we recommend the optimal material from our extensive range:

- High-performance polyethylene for an excellent balance of durability and cost-effectiveness

- Premium HDPE when superior strength-to-weight ratio is essential

- Industrial-grade PVC for extreme durability requirements

- Specialized coatings for specific environmental challenges

- Reinforced constructions for high-stress applications

3. Precision Manufacturing

Our state-of-the-art manufacturing facility brings your custom tarpaulin to life:

- Computer-aided cutting ensures dimensional accuracy within tight tolerances

- Advanced heat-sealing technology creates joins stronger than the base material

- Reinforced stress points prevent failures at vulnerable areas

- Quality control checks at every production stage

- Final inspection against the original specification

4. Professional Installation Support

For complex installations, we provide comprehensive support:

- Detailed installation guides tailored to your specific design

- Telephone support from the fabrication team who created your tarpaulin

- On-site installation assistance for complex projects

- Training for your team on proper deployment and securing

Industry-Specific Custom Tarpaulin Applications

Construction Sector Solutions

Construction sites present unique challenges that off-the-shelf products rarely address effectively:

Specialized Scaffolding Covers

Our custom scaffolding enclosures provide:

- Exact fit to the scaffold dimensions

- Integrated access points aligned with your work areas

- Weather protection while maintaining ventilation

- Flame-retardant options for compliance with site safety requirements

Case Study: For a historic building restoration in Edinburgh, we manufactured custom tarpaulins with transparent sections strategically positioned to allow natural light to reach sensitive restoration areas while providing complete weather protection during the 18-month project.

Concrete Curing Protection

Critical curing processes require precise environmental control:

- Temperature-regulating materials for optimal curing conditions

- Custom sizes to fit exact pour dimensions

- Specialized layering for moisture retention

Equipment Protection Systems

Valuable construction equipment demands customized coverage:

- Fitted covers for specialized machinery

- Access points aligned with maintenance requirements

- High-visibility markings for site safety

Agricultural Applications

Farming operations benefit from tarpaulin solutions tailored to agricultural realities:

Crop and Harvest Protection

- Custom-sized field covers for specific crop rows

- Specialized ventilation to prevent crop damage

- Easy deployment features for seasonal application

Livestock Area Covers

- Custom designed for specific pen and yard dimensions

- Optimized light transmission for animal welfare

- Reinforced mounting points for secure installation in rural environments

Customer Experience: A dairy farm in Yorkshire approached us needing covers for feed storage areas with very specific dimensions and access requirements. Our custom solution included easy-open access flaps and extra reinforcement at high-wear points, resulting in a solution that has outlasted their previous standardized covers by over three years.

Industrial and Manufacturing Custom Solutions

Industrial environments present some of the most demanding challenges for protective coverings:

Machine and Process Covers

- Precise fitting around complex equipment

- Heat-resistant materials where required

- Chemical-resistant formulations for specific environments

- Antistatic options for sensitive electronics

Warehouse and Storage Solutions

- Custom inter-bay covers

- Loading dock protection systems

- Temporary containment areas

Material Handling Protection

- Custom-shaped covers for irregular loads

- Reinforced securing points for transportation

- Weather-resistant packaging for export shipping

Marine and Coastal Applications

Waterfront environments demand specialized solutions to handle unique challenges:

Boat and Vessel Covers

- Hull-hugging designs for perfect fitment

- Ventilation systems to prevent damaging condensation

- UV and saltwater resistant materials

- Access points aligned with maintenance needs

Dockside Protection

- Custom coverage for loading and maintenance areas

- Tide-accommodating designs

- Corrosion-resistant fixtures and mounting points

Customer Insight: A commercial fishing operation in Cornwall struggled with premature deterioration of standard covers due to the harsh combination of salt spray, UV exposure, and regular handling. Our custom solution using specialized marine-grade materials has extended their replacement cycle from 8 months to over 3 years, significantly reducing their operational costs.

When to Consider Custom Tarpaulins

While standard tarpaulins serve many purposes effectively, certain situations make custom solutions the only practical option:

Irregular Shapes

When covering non-rectangular areas or equipment with protrusions, custom-cut tarpaulins eliminate excess material and improper coverage.

Critical Protection Requirements

When protecting high-value assets where failure isn’t an option, custom-engineered solutions provide peace of mind.

Difficult Installation Environments

When deployment must happen in challenging conditions, custom features like reinforced handling points and specialized fastening systems make installation possible.

Repeated Handling Requirements

When covers must be removed and replaced frequently, custom access features and handling points prevent premature wear.

Specialized Industry Compliance

When regulatory requirements demand specific materials or features, custom manufacturing ensures compliance.

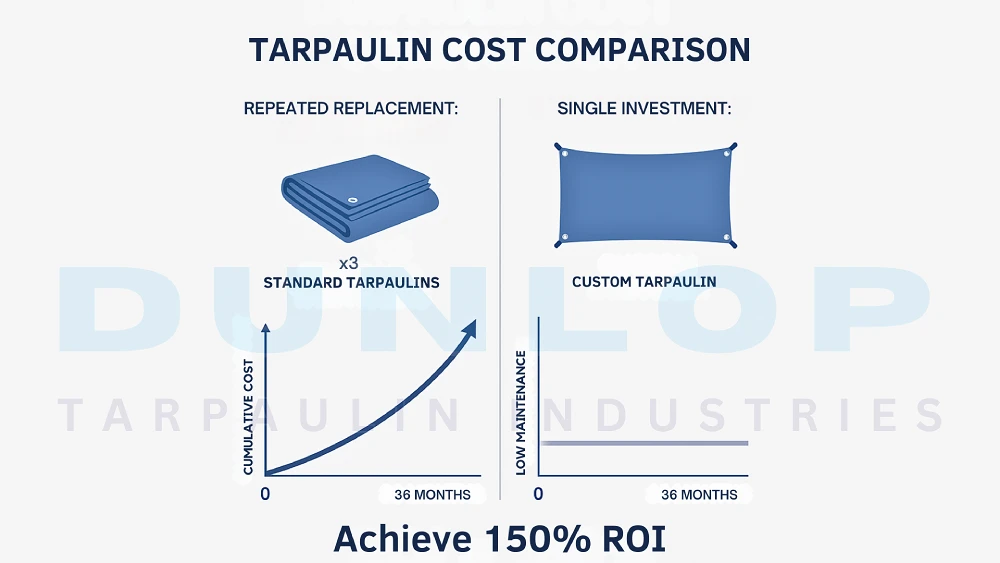

The Investment Value of Custom Tarpaulins

Custom tarpaulin solutions typically represent a higher initial investment than standard options, but the total value proposition becomes clear when considering:

Extended Lifespan

Perfect fitment eliminates stress points and movement that cause premature failure in standard covers, typically extending useful life by 40-60%.

Reduced Replacement Frequency

Our clients report an average 50% reduction in replacement frequency after switching to properly specified custom solutions.

Improved Protection Performance

Exact sizing and specialized features dramatically improve protection effectiveness, reducing damage to covered assets.

Operational Efficiency

Custom features like strategically placed access points and optimized handling elements save significant staff time during regular operations.

Getting Started With Your Custom Tarpaulin Project

Creating the perfect custom tarpaulin solution begins with a conversation. Our consultative approach ensures we fully understand your requirements before making recommendations:

- Initial Consultation – Discuss your requirements with our technical team

- Site Measurement – Exact dimensions taken (on-site service available)

- Material and Feature Specification – Collaborate on the perfect solution

- Manufacturing – Precision production to your specifications

- Delivery and Support – On-time delivery with installation guidance

Contact our custom solutions team today to discuss your specific requirements. With decades of experience creating bespoke tarpaulin solutions across multiple industries, we’ll help you develop the perfect protection system for your unique needs.

Last updated: April 2025

FAQ

Find quick answers to common questions.

Can I get a custom-fit tarp for my truck?

Yes, we make custom-fit tarps for trucks.

Can custom tarpaulins be weatherproof?

Yes, they can be waterproof and UV-protected.

Why choose custom tarps?

They fit better, last longer, and offer specialized protection.

Which industries use custom tarps?

Construction, agriculture, transportation, and events.